AEye announced its success of achieving a new standard for MEMS sensor reliability with the new 4Sight product based on its iDAR platform. The product surpassed automotive qualification for both shock and vibe in testing.

(Image: AEye)

AEye addressed the current issue in the LiDAR industry, which is how to attain solid-state performance, especially for high resolution at long range. Luis Dussan, co-founder and CEO of AEye noted that MEMS-based could be a potential solution for tackling the difficulties but the inability of FMCW or other TOF systems to effectively reduce the size of or harden their MEMS continues to be a stumbling block. AEye believes that its non-arrayed micro-MEMS is able to solve this challenge and provides the automotive industry a cost-effective solution with required reliability and performance.

The fifth-generation 4Sight, based on AEye’s iDAR™ platform, includes one laser, one MEMS, one receiver, and one SOC. Driven by extensible software, 4Sight is designed from the ground up to identify and deliver salient information while enable large scale manufacture at low cost. AEye recently engaged NTS, to conduct extensive shock and vibration testing, on the 4Sight sensor. The results of the test showed a 4Sight Sensor can sustain a mechanical shock of over 50G, random vibration of over 12Grms (5-2000Hz), and sustained vibration of over 3G.

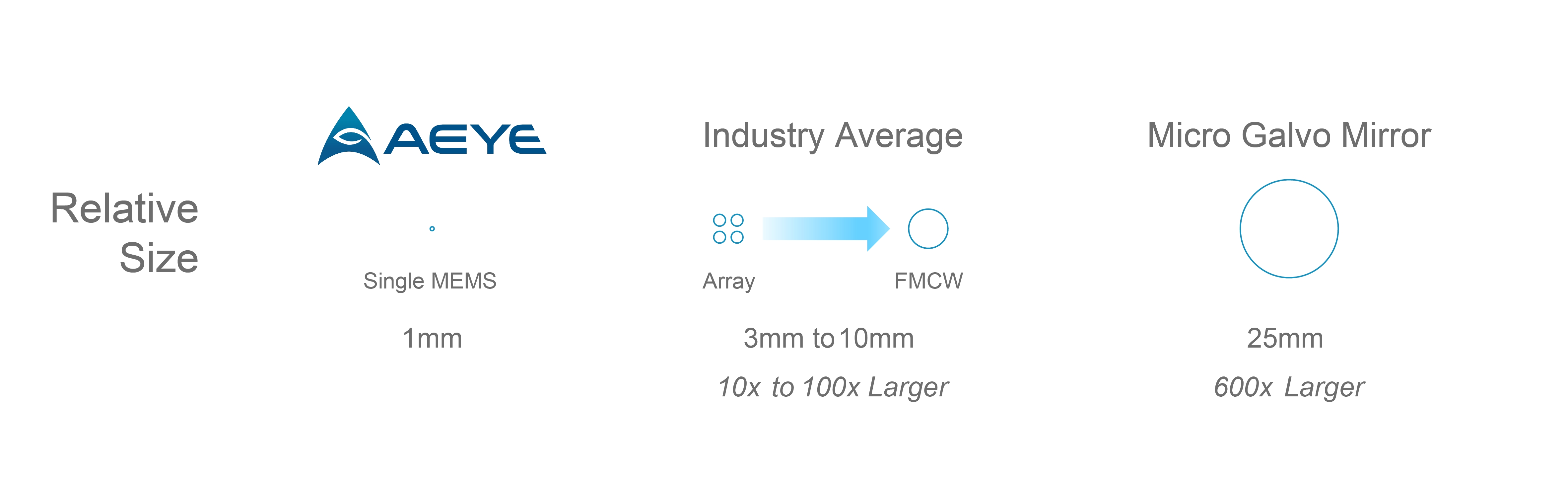

Size of the mirror in a MEMS is also critical that it largely determines its reliability. Larger mirrors also have larger inertia, generating 10x to 600x more torque from shock and vibration events. In addition, larger mirrors do not allow for fast, quasi-static movement for agile scanning, which is key to intelligent and reliable artificial perception.

(Image: AEye)

AEye’s MEMS allows a mirror that is less than 1mm in size. Other LiDAR systems use 3mm to 25mm mirrors – which equates to 10X – 600X larger surface area. (See above image) Combined with a 1550nm laser and receiver, the small mirrors in AEye’s MEMS are produced in volume using standard processes and deliver high performance and reliability.