Laser Components, a company providing comprehensive optoelectronics product lines, including Pulsed Laser Diodes, VCSELs, Si-APD-Array, and CMOS SPAD, for next generation LiDAR, announced cutting-edge advancements and achievements that are moving the sensors industry forward. In response to Automotive LiDAR and Rangefinder market demand, Laser Components has consistently expanded the capacity and successfully developed novel technique year by year. LEDinside / TrendForce was honored to have an exclusive interview with Winfried Reeb, Head of Business Unit Active Components, to share the latest progress and advances in the technologies of QuickSwitch Pulsed Laser Diodes (PLD) and photodiodes that usher in a new era of 3D imaging market to meet high-resolutions requirements for automotive industry.

Winfried Reeb, Head of Business Unit Active Components, Laser Components

Laser Components was founded 1982 in Germany as a company for the sale and production of lasers and optoelectronic components. The group has not only expanded to include five production facilities, but also has five sales organizations in Great Britain, France, Sweden, and the U.S.A. In addition, the company is working closely with some of the most important business partners and key suppliers to fulfill customer demand and requirements. In total, Laser Components employs roughly 250 people in six different countries.

Laser Components has been providing Pulsed Laser Diodes and Avalanche Detector for more than 20 years and has accumulated a wealth of experience in the automotive industry. Regarding laser diode requirements for LiDAR applications, discrete solutions available on the market usually have a pulse length of 5-10 ns. Reeb indicated that the standard QuickSwitch Pulsed Laser Diode with 2.5 ns pulse length and 90W is already a perfect match for the automotive LiDAR market. For all applications requiring higher peak power levels, custom arrays and special designs are able to be implemented. The huge benefit of shorter pulses is the ability to detect with a very high resolution at short and long distances. The other benefit is that LiDAR can work with higher peak power reaching 90W which allows measurement of longer distances while still being “eye safe” as those lower power laser. Furthermore, Reeb indicated that Laser Components consistently researched and developed Next-Generation Trenched Chip Pulsed Laser Diodes with high power, high stability, and more flexibility. Trenched Chip Pulsed Laser Diodes will be released in 1Q21.

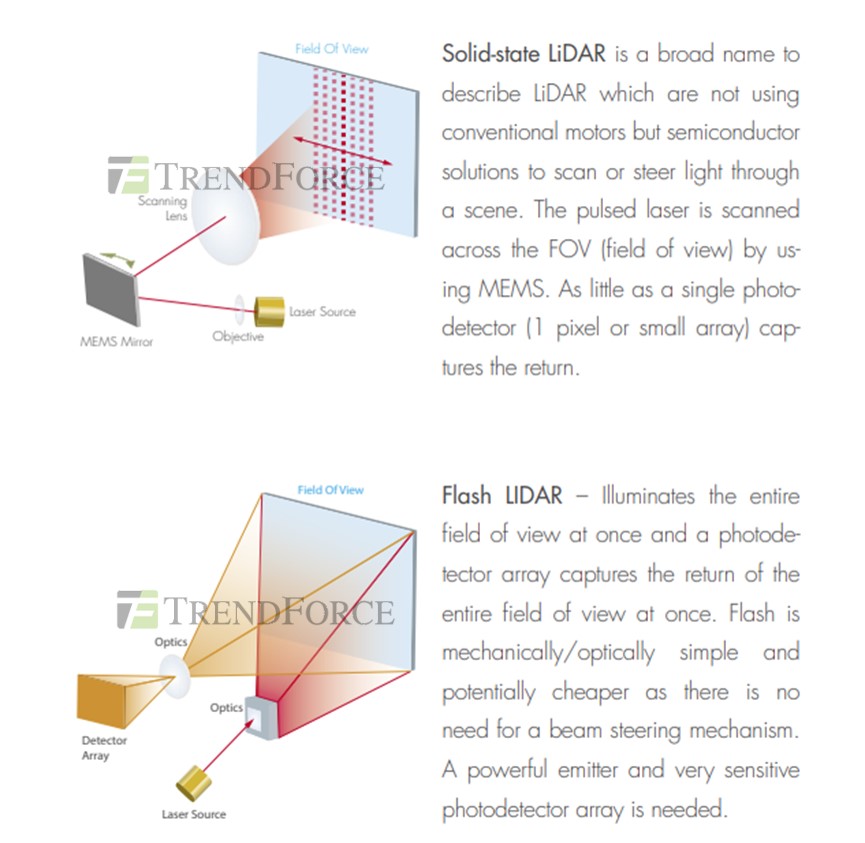

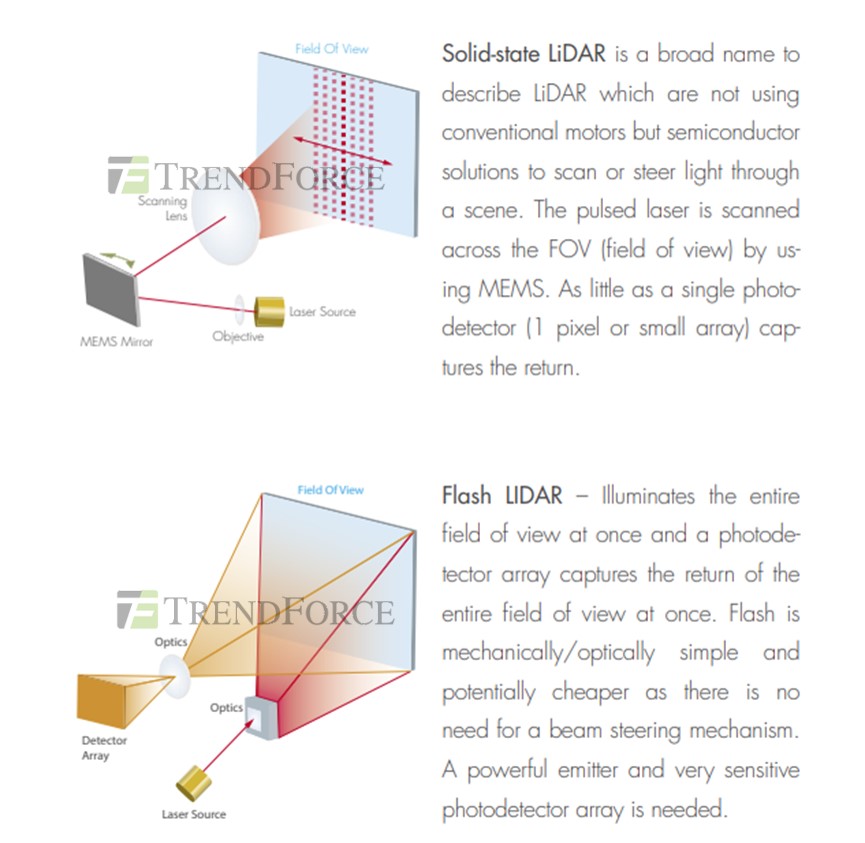

In addition to the LiDAR market needs, Laser Components has also provides photodiodes, including Si-APD arrays and CMOS SPADs. Linear Si-APD arrays include 8, 12, and 16 element arrays with 620 µm x 190 µm active area per element. Reeb indicated that the advantages of APDs include their small size, high sensitivity, fast speed response, and easy evaluation electronics, which is suitable for scanning LiDAR. A CMOS SPAD, on the other hand, possesses a high sensitivity but requires special electronics, which is suitable for flash LiDAR.

Regarding company achievements, Laser Components has successful achievements for laser diodes in automotive and industrial applications. It is hard to say how the overall economy will develop, especially under the COVID-19 epidemic situation. Nevertheless, Laser Components is confident that their novel and innovative products will create new market opportunities and fulfill customer requirement.

Author: Joanne / TrendForce

2021 Infrared Sensing Market Trend- 3D Sensing, LiDAR, SWIR LED

Release: 01 January 2021

Format: PDF

Language: Traditional Chinese / English

Page: 175

|

If you would like to know more details , please contact:

If you would like to know more advertising details , please contact:

|