Vancouver WA – eLux, Inc. is pleased to announce the successful achievement of two important milestones in the drive to commercial development of microLED displays.

-

Optimization and automation of the fluidic assembly process with selective harvest of microLEDs has produced a 12.3” microLED display with a natural yield of 99.987%.

-

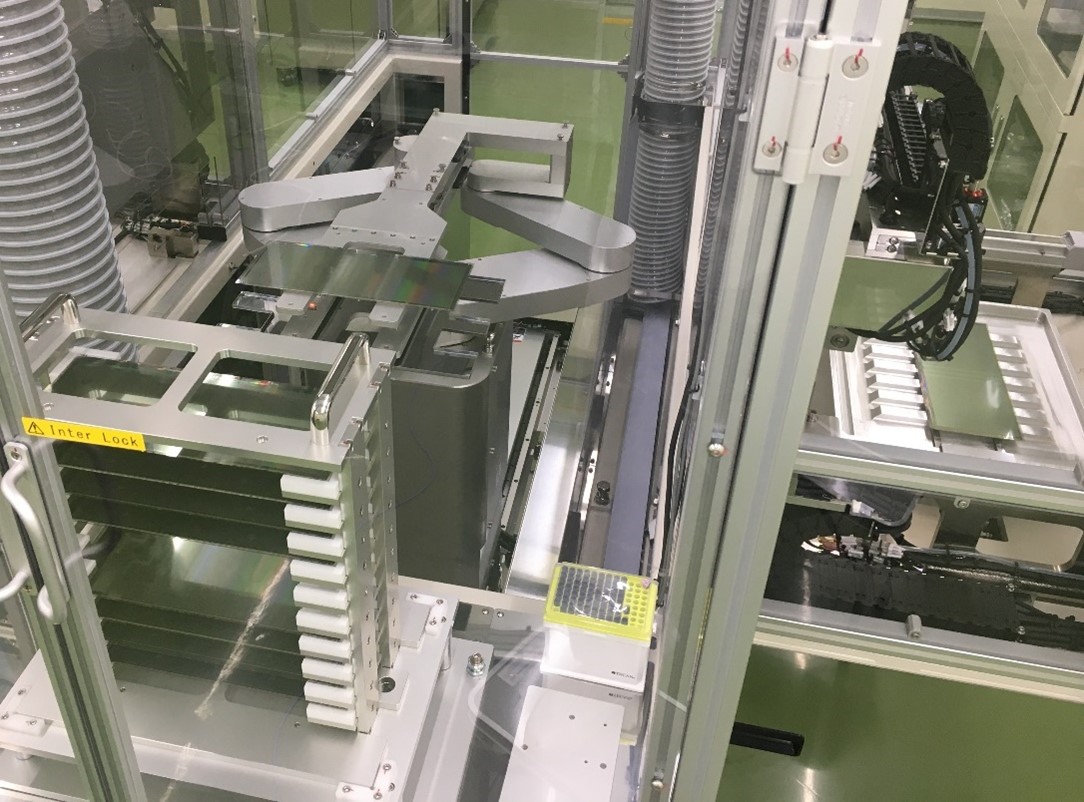

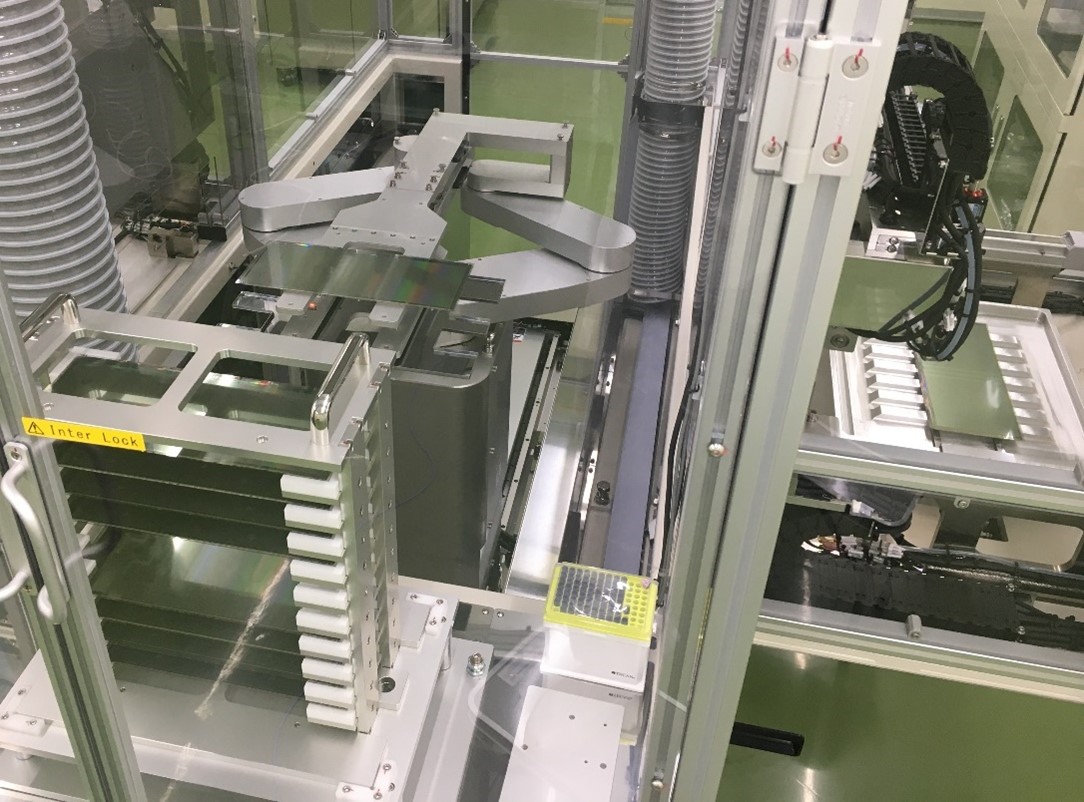

An automated fluidic assembly tool manufactured by an accomplished display panel tool maker is operational in the eLux prototype fab located at Taiwan.

The 12.3” demonstration display with 99.987% natural yield consisted of 518,400 GaN microLEDs assembled in 10 minutes for an assembly rate of 3.1 million devices per hour. There were 34 failing subpixels, of which 33 could be laser repaired to achieve after repair defectivity approaching one part per million. Given that a 4K television has 8.3 million pixels this result is approaching the quality level require for a microLED television. Of the 34 defective sites 19 were caused by shorted microLEDs so additional refinement of the inspection and selective harvest processes will be required to produce defect free displays that do not require repair.

The new assembly tool shown in the photo has demonstrated fully automatic cassette-to-cassette fluidic assembly of ten display panels up to 15” diagonal. The tool has provisions for capture and recycle of microLEDs and assembly fluids to minimize operating costs, and two additional modules can be added to the main frame for increased capacity. The manufacturing process includes automated inspection at each stage (assembly, clean-off, recycling and drying) for throughput optimization and yield enhancement. Unlike mass transfer equipment, fluidic assembly can be scaled up to substrates much larger than 15” so this tool will be used to develop equipment modules and processes for a proposed Gen 3.5 fluidic assembly tool.

eLux proprietary fluidic assembly technology has several significant advantages over conventional mass transfer methods used for competing microLED displays. Most important is that massively parallel assembly can achieve assembly rates over 5 million devices per hour using simple equipment and assembly can be scaled up to Gen 6 backplanes. Inspection and selective harvest techniques developed by eLux prevent defective microLEDs from entering the assembly process, so displays are fabricated using only known-good microLEDs. Fluidic assembly randomizes the microLEDs in liquid, which prevents the mosaic patterns caused by epi-wafer non-uniformity. The fluidic assembly methods are quite gentle so GaN microLEDs grown on PSS substrates or brittle AlGaInP red microLEDs have been demonstrated. The technology is suitable for microLEDs sized between 5 and 200 microns offering flexibility to make a wide variety of displays. eLux, Inc., with headquarters in Vancouver WA, was founded on October 13, 2016 as a spin-out from Sharp Laboratories of America. eLux has developed low-cost direct emission displays based on microLED technology targeting large format displays for video wall and television applications. Development of fundamental microLED assembly technology is carried out in the US, while prototype displays are made in our lab in Taiwan. eLux holds 56 US and 37 foreign patents with an additional 31 pending applications covering all aspects of the fluidic assembly technology for microLED based displays.

For additional information see the eLux website: https://www.eluxdisplay.com/

Automated fluidic assembly tool

12.3” display with 99.987% natural yield

Source:eLux

TrendForce 2021 Self-Emissive Micro LED Display Trends and Manufacturer Strategy Analysis

Release Date: April 30, 2021

Language: Traditional Chinese / English

Format: PDF

|

For further information about the report, please contact:

|

|

|

|

|

Global Contact: |

ShenZhen: |

Grace Li

Tel : +886-2-8978-6488 ext 916

E-mail :Graceli@trendforce.com |

Perry Wang

Tel : +86-755-82838931 ext.6800

E-mail : Perrywang@trendforce.cn |