▲ Francesco Lemmi, Program Director of Films at Zymergen, came to Touch Taiwan 2021 to share the innovative display applications that are made possible with the offerings from the Hyaline family of PI films.

As a revolutionary next-generation display technology, Micro LED was certainly a thematic focus at this year’s edition of Touch Taiwan, which has long been a major display industry trade show. Many companies including display panel manufacturers and LED manufacturers set up exhibitions to demonstrate their technological capabilities in the development and production of Micro LED displays. On the other hand, Micro LED displays are an integration of the most cutting-edge technologies from many sectors in addition to semiconductor, display panel, and LED. Innovations in the upstream sections of equipment and materials, therefore, drive the ongoing progress in the development of Micro LED displays. As a provider of advanced materials, Zymergen intends to play a key role in helping manufacturers of Micro LEDs and Micro LED displays develop new products. .

Micro LED is being touted as the state-of-the-art display technology of our age even though there is still some distance to go before it can formally enter the market. After the challenges related to mass production have been overcome, Micro LED is expected to provide a much superior viewing experience compared with the existing display technologies. Furthermore, it is expected to open up a wide range of unique and integrated applications that are highly anticipated by the display industry. To realize the potential of Micro LED, a transparent PI material that is flexible and tolerates high temperatures can now serve as a key material in the design of a futuristic display system as well as the starting point for the exploration of new display applications.

▲ Zymergen introduced its transparent PI optical films under the Hyaline family at Touch Taiwan.

Based in the US, Zymergen is not simply a material supplier. Its products such as PI optical films attract growing attention from companies across numerous industries because their development is not confined within the conventional manufacturing processes for industrial chemicals. In the creation and commercialization of new materials for specific uses, Zymergen combines biology, AI, and automation. Its “biofacturing” platform enables differentiated properties and material characteristics, and can potentially shorten the development time and offer a cost advantage.

Francesco Lemmi, Program Director of Films at Zymergen, was at the International Micro/Mini LED Display Conference 2021, which was one of the main programs during this year’s Touch Taiwan. In his presentation on the advantages and uses of the Hyaline Z2 PI optical film, Lemmi said that the goal of his company is to “launch products in about half the time and at one-tenth the cost of traditional chemistry.”

For decades, manufacturers of PI materials have been developing the same set of molecular building blocks because the cost and complexity of using new monomers has been a barrier. Consequently, the product development process for PI materials lacks innovations and leads to undesirable trade-offs between material properties and material performance. Richard Pieters, President of Products at Zymergen, stated that his company uses both popular and complex building blocks. “Zymergen draws inspiration from the natural world as it synthesizes new kinds of polymer,” said Pieters.

Besides Micro LED, target applications of Zymergen’s thin PI films also include foldable devices, under-panel cameras, and automotive electronics

PI materials can be used as the substrate material in the production of Micro LED displays. The Hyaline family of PI films from Zymergen will offer excellent properties for a number of applications. For example, heat tolerance and a glass-transition temperature that is above 300 degrees Celsius, making it suitable for the soldering process that takes place during the transfer of Micro LEDs onto a PCB. Being flexible and colorless can also enable things like curved displays, automotive displays, and transparent displays. Apart from serving as the substrate material, the Hyaline films also have the right properties to be purposed for the mass transfer of Micro LEDs.

Zymergen is bullish on the development potential and market prospect of Micro LED. It is therefore actively collaborating with other companies that are involved in this field so as to develop lines of products that specifically address the manufacturing requirements of Micro LED displays. In terms of expertise and experience, Zymergen has already established itself as a provider of advanced materials for displays and other kinds of electronics, giving it a favorable position to enter the field of Micro LED.

Zymergen made the decision to develop PI materials for electronics in 2018, and the official launch of the Hyaline Z2 film took place a few years later in 2020. The Hyaline Z2 film has outstanding optical properties with respect to transparency, haze, and yellow index. For flexible displays, the high optical transmittance of the Hyaline Z2 contributes to an increase in brightness and a longer battery life. The material has exceptional mechanical and electrical properties as well. It has a high level folding endurance at a small radius and can provide a much longer lifespan for foldable devices compared with conventional PET and COP materials. In the near future, Zymergen’s material technologies are expected to be adopted for foldable smartphones and tablets.

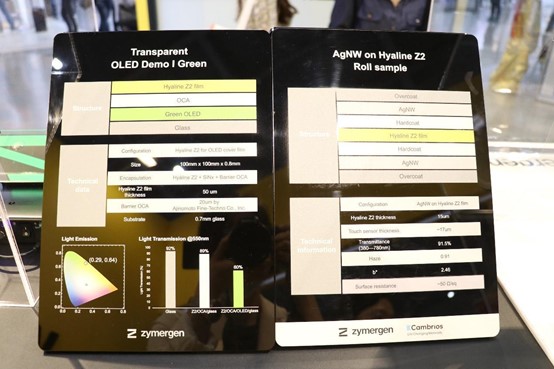

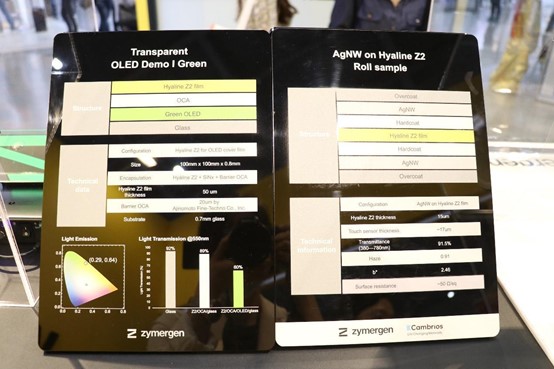

▲ At Touch Taiwan 2021, Zymergen demonstrated two transparent OLED displays that incorporate the Hyaline optical film.

▲ The pamphlet at the display booth provided details on the specifications and properties of the Hyaline optical film.

Apart from foldable devices, Zymergen also wants to focus on the use of the Hyaline films in the development of under-panel (or in-display) cameras for smartphones. While other materials may offer a high level of fold endurance, the Hyaline films have additional optical and electrical attributes such as high optical transmittance, low yellow index, low haze index, and low phase noise. The rival materials that have been used as the backplate for an under-panel camera tend to be thicker and absorb more light. By contrast, Zymergen’s thin-film technology with its best-in-class optical properties can help smartphone cameras transcend their past limitations and realize a true under-panel design.

Automotive electronics and displays constitute another major target application for Zymergen’s Hyaline films. The materials and components related to automotive electronics are tested to their limits in terms of durability and reliability under extreme conditions. In this application segment, the Hyaline films can be purposed as a colorless EMI shielding material or a supporting layer within a thicker EMI shield on account of their heat tolerance and structural stability.

Also, the advantages pertaining to optical properties can be leveraged in the development of automotive displays. For instance, the high optical transmittance of the Hyaline films translates to higher brightness and power saving. Moreover, the Hyaline films have low birefringence. This minimizes the issue of mura and enhances image quality.

Zymergen expands its local teams in Taiwan and Japan as it focuses on the advanced materials for the electronics industry

While Zymergen has a product portfolio that encompasses numerous sectors and applications, the Hyaline Z2 product is being offered now to the electronics industry. At this year’s Touch Taiwan, Zymergen announced that it is growing operations in Taiwan and Japan. The company aims to form partnerships with the leading electronics companies based in the Asia-Pacific region and become their key material supplier.

Commenting on Zymergen’s strategy, President of Products Richard Pieters said the following: “A wealth of electronics customers in the Asia-Pacific region are seeking cutting-edge materials to advance their consumer electronic products and stay ahead of the competition. Hence, growing our team in the region is essential to build on our network of manufacturing partners in the electronics industry and deliver our Hyaline product at scale.”

Kenny Hsu, who is the Global Sales director for electronics at Zymergen and a founding member of the Taiwan team, said: “We have seen strong interest in the Hyaline films from electronics manufacturers as this series of thin-film materials performs brilliantly in many respects.”

Through “biofacturing” innovations and close ties with industry leaders, Zymergen expects to introduce the Hyaline films to many application segments. Possessing many points of differentiation compared with other materials, the Hyaline films can find uses in a diverse range of end products. At the same time, customers in the electronics industry within the Asia-Pacific region are searching for more innovative and cost-competitive material technologies that can give them an edge in the development of end products.