Personalized, self-determined and decentralized – the healthcare sector is changing, with digitalization as the prime mover. And miniaturized sensors are the key.

Life as a patient in ten years’ time will be significantly different from what it is today. Smartphones and wearables will be doing much more than just taking photos and sending messages. They will be helping us to stay healthy.

Whether through wearables, rapid digital testing or smartphones with extra functionality, digitalization is fundamentally changing the health sector. And with it healthcare for everyone. Healthcare will be more personalized, self-determined and independent of location. Infectious diseases will be better managed, life-threatening diseases detected earlier and chronic diseases monitored more easily. Algorithms will warn us if we are about to reach critical values. And artificial intelligence, with links via the cloud, will support medical decisions – even for people living far away from medical centers.

These developments will be made possible by sensors as they get smaller and smaller, smarter and smarter. Digitally processed light, which can shine through skin and tissue right down to the blood vessels, is opening up completely new possibilities. Thanks to increasing digitalization and rapid development of deep learning, we will be able to observe a wide range of health-related parameters round the clock at home.

Next generation diagnostics

These developments are still in the early stages, but the Covid pandemic has given them a boost. “We were working on digital healthcare solutions at the point of need long before Covid-19,” says Alexander Volk, one of the pioneers in connected health solutions at ams OSRAM. “We started by developing spectroscopy solutions for analyzing medicines and food and for determining skin parameters such as moisture. Our latest product, the sensor-based Covid-19 rapid lateral flow test kit, is just the first in a series of digital health tools.”

The flow test involves dripping the test specimen onto a test strip. A biochemical reaction between antibodies and the molecules to be detected leads to a change in color. A spectral sensor in combination with a light emitter can detect the colors or fluorescence behavior. The sensor is connected to a Bluetooth-enabled microcontroller from which the values can be read and transmitted to a smartphone and a medical certified cloud environment. The results are therefore immediately available in electronic form.

But it's not just about viruses. Rapid, high-precision tests are also required for monitoring ovulation or vitamin levels. Tests for vitamin levels are particularly important for people who regularly take medication. Tests that can be carried out easily at home would represent real progress in identifying illnesses which do not merit a visit to a doctor. That’s a good reason for Alexander Volk and team to continue working on rapid, high-sensitivity tests for a variety of parameters.

Light that gets under the skin

Wearables for measuring certain vital functions are another cornerstone of digital health monitoring. They first appeared in the 2010s as fitness monitors but are now much more accurate and informative. They use light-emitting diodes to shine light through skin and tissue for measuring heart rate and oxygen saturation. A sensor records and evaluates the level of absorption of hemoglobin. “With our know-how in the production and detection of light, we can continually improve the degree of accuracy. We are working together to create optical systems from a single source so that individual components are perfectly matched,” says Volk, highlighting the opportunities that the new combined ams OSRAM company brings.

Small will be huge

There are some technical challenges to overcome before mobile, cost-effective and easy-to-use solutions can be offered for services previously provided only by laboratories and medical practices. More than anything else, modules need to be significantly smaller. Complex systems consisting of a light emitter, associated detector and connecting optics have to be accommodated in just a few cubic millimeters.

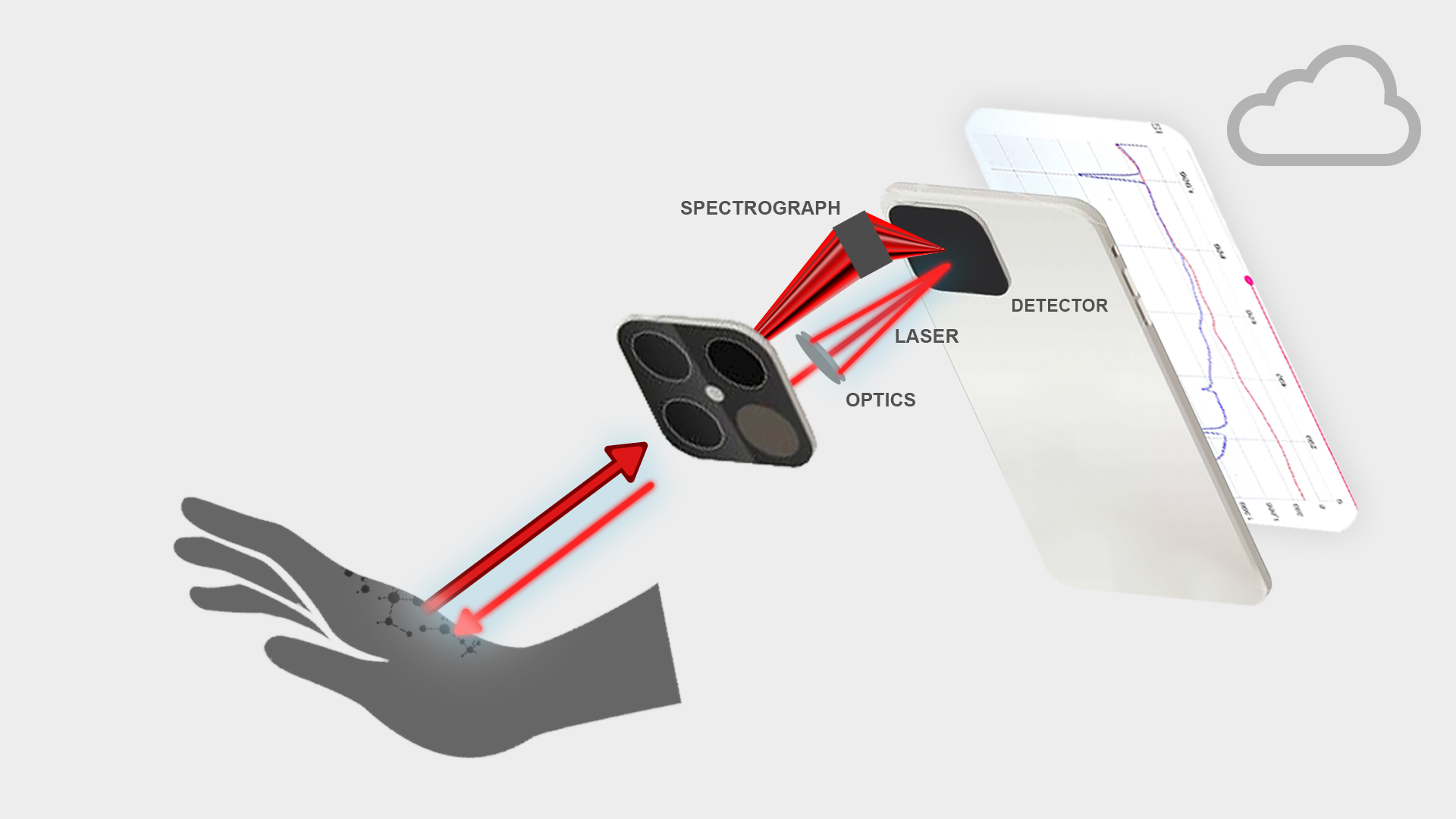

Developers at ams OSRAM are working on such solutions, including ones for measuring parameters such as the levels of glucose, lactate, cholesterol and urea. Measuring the spectral fingerprint of molecules with so called molecular spectroscopy is a particularly promising technology here. It now needs to be miniaturized. The interaction between light and matter provides insights into the properties of a sample. A laser is fired at a sample, and the spectrum of the light scattered on the sample is then measured. A very small portion of the reflected light differs from the emitted in intensity or frequency, which provides information about the substance under investigation.

Miniaturizing the technology so that it’s suitable for everyday use is the key to medicine of the future.

Shrinking spectroscopy

Up to now, suitable spectrometers have been available in laboratories, operating with very sensitive and in many cases cooled photodetectors and semiconductor image sensor CCD cameras. Even the portable versions that are currently used in forensics, for example, are too large to integrate in cell phones or wearables.

Together with Johns Hopkins University in the USA, ams OSRAM is now working on a mobile solution. The university is supplying the medical model and supporting laboratory setups, while the company is working on miniaturizing the technology for everyday use.

Alexander Volk describes the enormous technical challenge: “The entire system needs to work without cooling, with minimum power consumption, with only a fraction of the pixel count and in mini chip format.” The signals that the system receives from the body or from the sample are very small and have to be amplified noise-free. A light source is also needed that can produce light of uniform intensity over long periods of time. Another challenge is to develop high-precision optomechanical components that are permeable only for light of a defined wavelength and to integrate them in the mini chip.

None of that will be easy. But once the challenges of miniaturization and integration have been resolved the path will be clear for mobile health monitoring for all. And for completely new medical insights and treatment options as a result.