Due to the recent outbreak of COVID-19, there is increased interest for disinfection and sterilization devices. Portable UV sterilization devices equipped with UVC

LED are made to be light and small, offering sterilization on the go, making it a popular option for everyday use.

▲ A stylus equipped with UVC LED for sterilization of pad device screens, made using ViviOn™. This is a product of the company, Adonit.

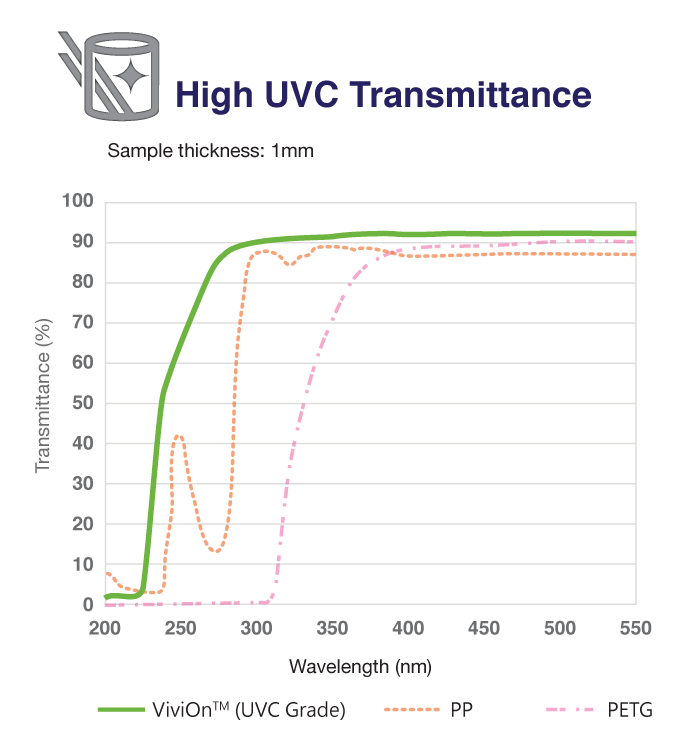

USI Corporation’s ViviOn™ is a medical grade polymer, with high UVC transmission and UVC durability properties. For parts made with ViviOn™ (thickness 1mm), transmission can reach 79 – 88% in the wavelength range of 265 to 280nm. This is an attractive property for home appliance manufacturers, as ViviOn™ can be made into light covers, shielding and disposable devices. Currently there are commercial products such as the portable sterilization boxes from the companies Sandra and Moshi, and the stylus from the company Adonit with sterilization capability.

USI Corporation is founded in 1965, with over 50 years of experience in developing and manufacturing polymers of high quality. Over the recent years, USI Corporation made rigorous efforts to develop high value-added polymer materials, introducing a novel Cyclic Block Copolymers (CBC) - ViviOn™ in 2018, a medical and food contact grade polymer with high UVC transmission properties. Continuing the efforts, USI Corporation is committed to making ViviOn™ the most suitable material for UVC sterilization applications. In 2020, ViviOn™ also received the Inno Award, an event organized by the Institute for Biotechnology and Medicine Industry (IBMI), Taiwan.

▲ViviOn™ with higher UVC transmission than other polymer materials.

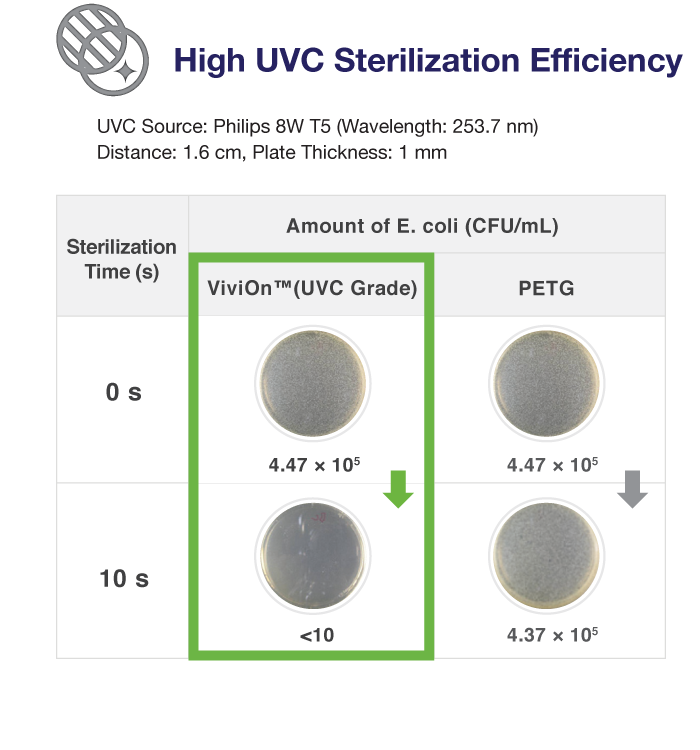

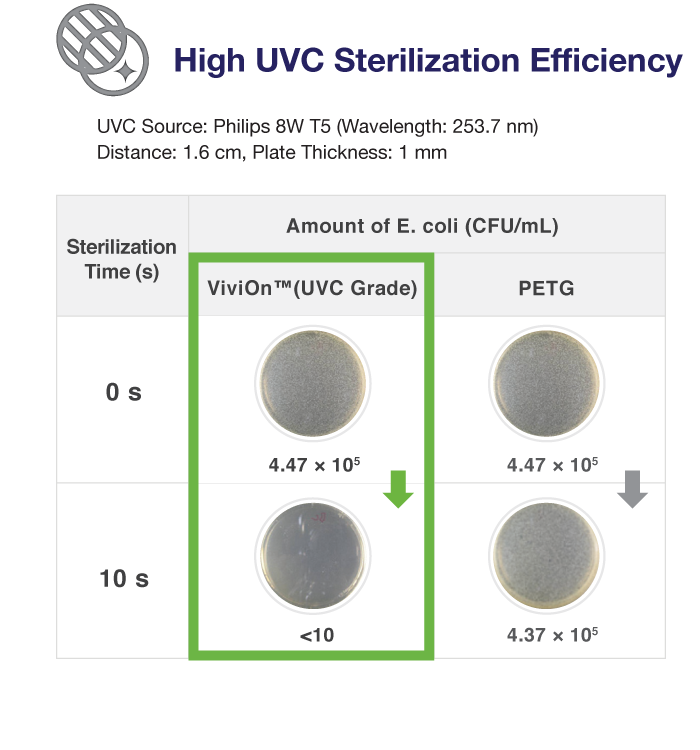

▲ViviOn™ is significantly more effective for UVC sterilization than other polymer materials.

ViviOn™ is a material with higher UVC transmission and UVC durability than other polymer materials, making it more effective when made into a portable UVC LED sterilization device. It is also less prone to yellowing after long term exposure to sunlight. ViviOn™ resins can be processed just like all other thermoplastics, it can be injection molded or extrusion molded into UVC LED light covers, shielding or disposable devices with design flexibility. When ViviOn™ is used as a replacement material to Quartz, the weight of the product can be decreased, and the product will be resistant to breakage, increasing product safety.