Otsuka Electronics Korea, having a history of display front-end measurement solutions, released a superior model of the HS-1000H series on the market. This latest one has been specially designed for Mini-

LED and Micro-LED, which are very delicate as each micro-sized chip emits lights. As the existing model lines are trusted in the Mini-LED BLU optical inspection process, the new model also aroused many expectations.

To be responsible for quality inspection of advanced display technology, Otsuka Electronics Korea combined a 120-megapixel camera with global criteria spectroradiometer (MCPD), and established this ultra-high-speed imaging luminance-colorimeter. HS-1000H is literally taking a 2D image in a single shot but with multiple results of each pixel characteristic such as brightness and intensity. At the same time, by gathering individual features identified, it is possible to check the quality of the entire display: color difference, luminance and color uniformity, pixel defects, white balance, color gamut, contrast ratio, and even pass-or-fail judgment of lens encapsulation on surface mounting process.

As mentioned above, new display technologies such as Mini-LED and Micro-LED tend to have self-luminescence elements. High resolution of 120-megapixel camera performs accurate quality inspection and correction against small pixels without missing a single one. HS-1000H enables the yield of the display production line to be significantly improved by recognizing the characteristics of each pixel and inspecting the entire display quality at once.

The fact that HS-1000H was able to take charge of both Mini-LED BLU and Micro-LED quality inspection was also contributed by its own software. Exclusively made software that combines point and surface luminance meters allows high-speed measurement of high-resolution images up to 120 million pixels. It provides functions for user conveniences like spatial and luminance distortion compensation, an additional compensation according to the viewing angle characteristics of the sample, and Smart active area detection.

With the HS-1000H release, Otsuka Electronics Korea aims to become a more reliable inspection equipment manufacturer in the optical compensation process and quality inspection process leading to a new trend in display manufacturing through continuous R&D.

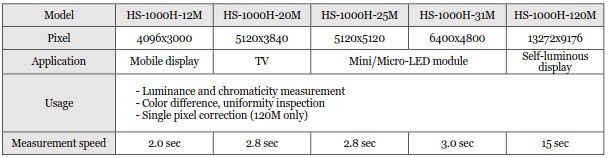

Specifications of HS-1000H