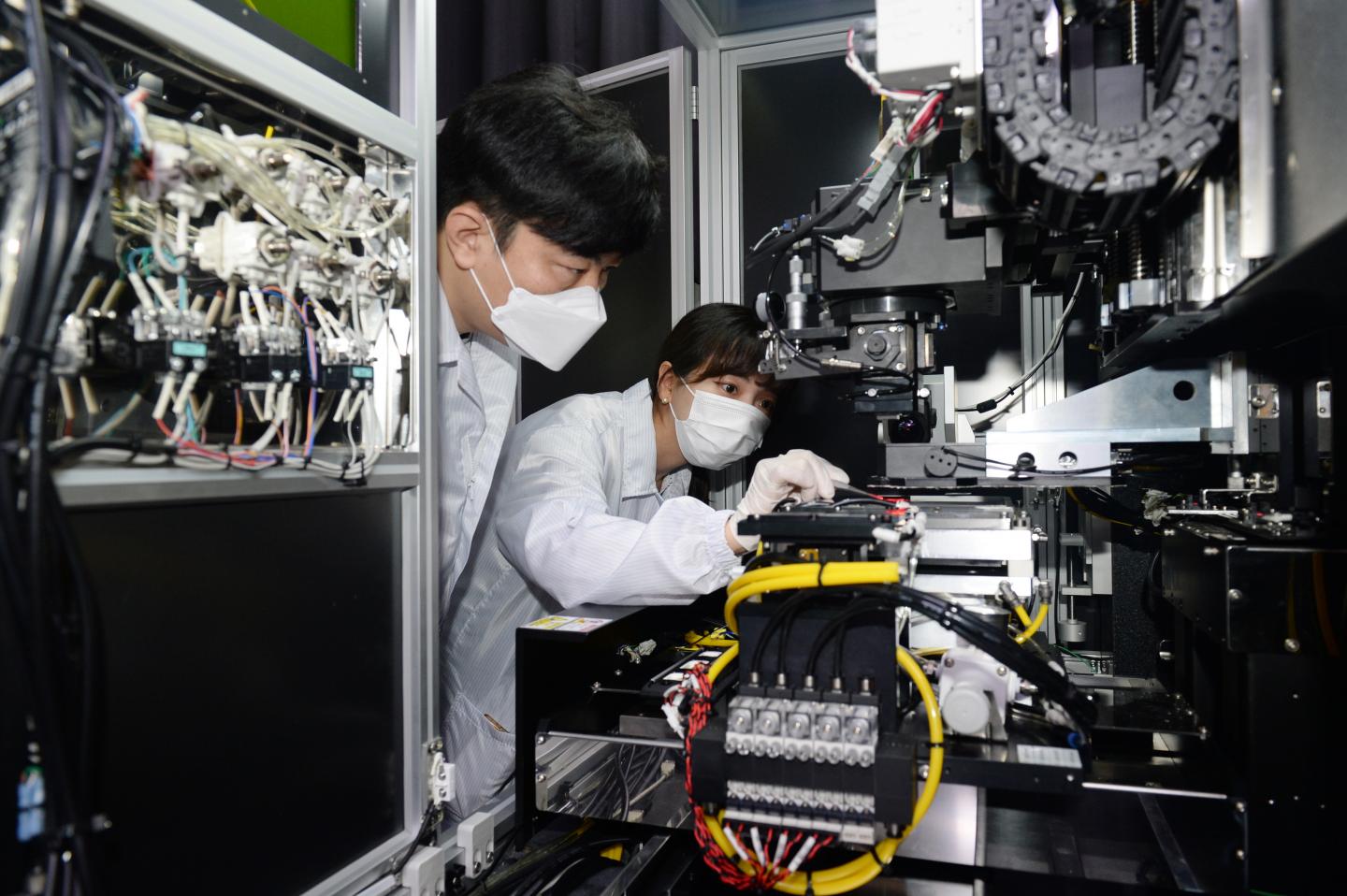

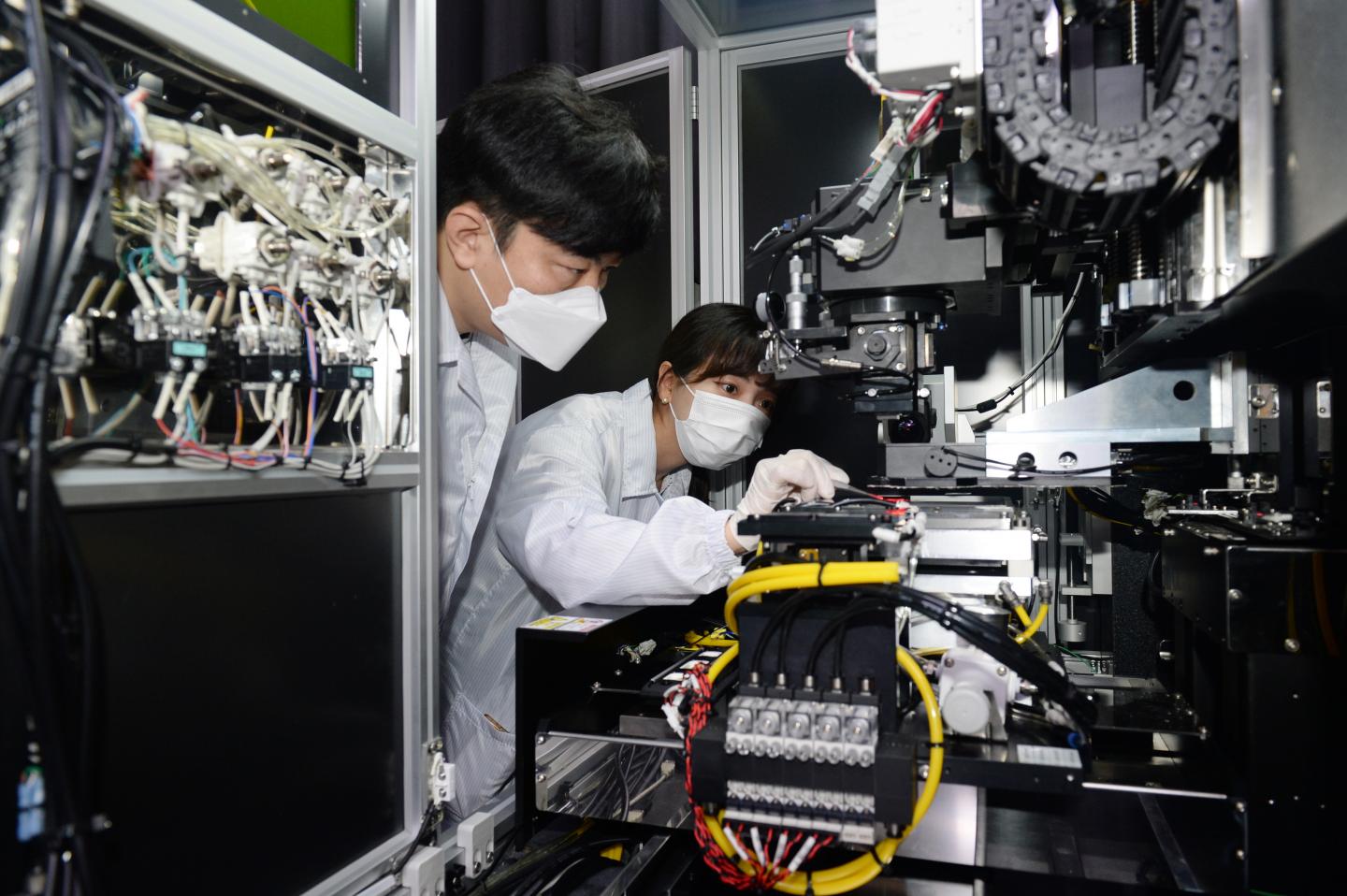

IMAGE: RESEARCHERS FROM ETRI IS PERFORMING THE SIMULTANEOUS TRANSFER-BONDING PROCESS FOR MICRO LED

The Korean research team developed the world's first next-generation display technology that can simplify the process and reduce the incidental expenses considerably. The new materials required for the new process were also developed for the first time in the world and is expected to support the Korean industry considerably in continuing its leadership in the next-generation display market.

Micro LED display is a next-generation self-emitting display using micro LED2)as pixel light source. The research team fabricated 12 micro LEDs in 1mm2, and more vivid color can be realized compared to the LCD3) or OLED4) display. It also has such high luminous efficiency that it can be utilized in various fields such as TV and Smart watch, etc.

To develop the product, micro LED produced through the semiconductor process must be transferred to the display panel. For 8K TV, about 100 million micro LEDs are required, and the size is also very small that a long time for transfer and bonding is required. The materials required for manufacturing the display are also dependent on import, so the price is very high5).

The research team applied homogenized laser to the SITRAB film attached to the micro LED for a few seconds to develop the core process of simultaneous transfer and bonding7) to overcome the challenge.

By applying the technology developed by ETRI, the high investment costs that used to be required for the transfer and bonding equipment can be reduced, and the process can be simplified to increase the manufacturability. In addition, the newly developed materials can be attached with additional micro LEDs even when applied with laser several times for enhanced convenience of repairing the defective pixels8). Therefore, the limitation of the existing process, ie, not being able to perform repair, can be solved.

Especially, the transfer and bonding material that was mostly imported from Japan could be secured to create a new market through the new material development without the need for local manufacturing. The developed technology can also be utilized with domestically developed equipment instead of the expensive foreign equipment, making it favorable for commercialization.

The research team attributed this result to efforts for the development of the relevant equipment and process based on know-how researched on the differentiated new material technology for 16 years by ETRI. ETRI expects the relevant products such as smart watch and TV, etc. to be commercialized within 2 years by transferring the technology to Korean display companies, etc.

Release Date: 30 April 2021

Language: Traditional Chinese / English

Format: PDF

|

If you would like to know more details , please contact:

|