News Facts:

-

With its on-chip photodiodes, ams OSRAM's AS5951 offers a cost-effective solution for 32-slice detectors of Computed Tomography scanners in the price-sensitive market segment

-

Thanks to the monolithic integration of the A/D converter, the photodiode array and the voltage reference into one single component, the AS5951 facilitates system development and reduces the cost of materials

-

Low noise performance and low photodiode leakage current ensure high image quality and low dose performance

With its on-chip photodiodes, ams OSRAM's AS5951 offers a cost-effective solution for 32-slice detectors of Computed Tomography scanners in the price-sensitive market segment

Premstaetten, Austria (27 October 2021) --

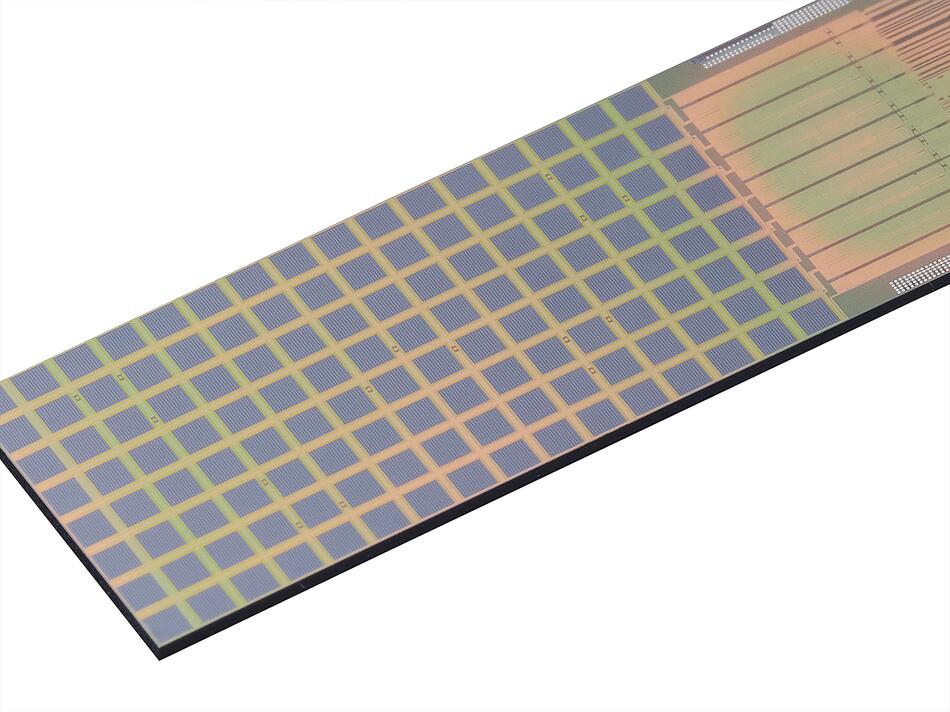

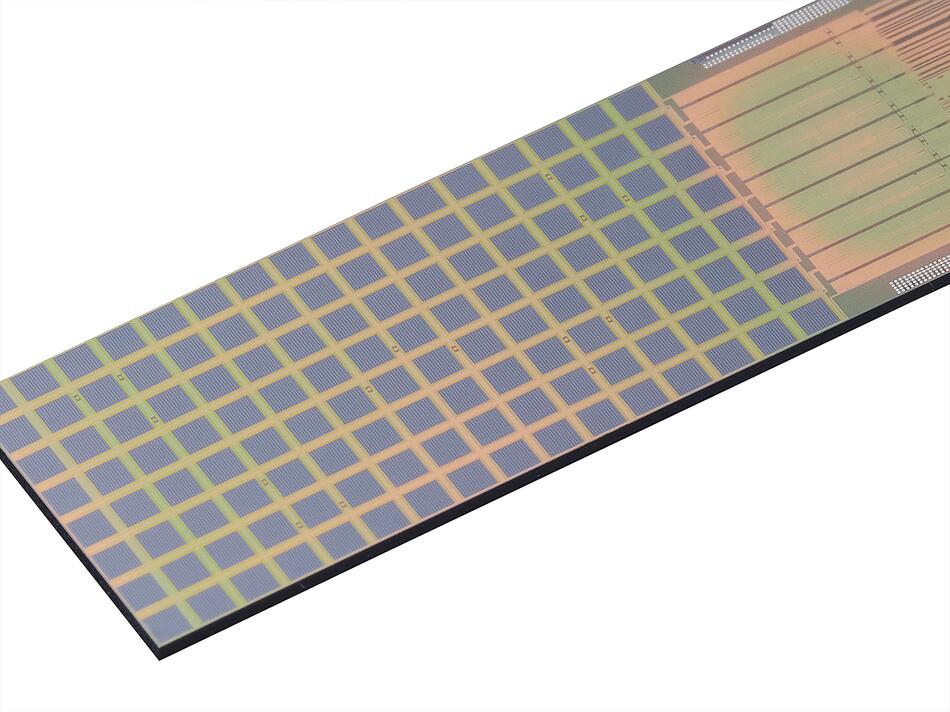

ams OSRAM (SIX: AMS), a global leader in optical solutions, expands its sensor chip portfolio with a 32-slice solution for

Computed Tomography (CT) scanners. CT devices are used in a wide variety of fields such as medical, industry or security. Across all applications, the decisive factor for developing a cost- efficient CT scanner is the detector. “The AS5951 sensor chip from ams OSRAM simplifies the detector assembly. It combines highly-sensitive photodiode arrays and readout circuitry in a single CMOS chip. Compared to its predecessor, the AS5951 delivers improved image resolution for the same sensor area,“ says Jose Vinau, head of the Medical and CMOS segment at ams OSRAM.

Next generation sensor chip

The main improvement over the previous

AS5950 is the increased spatial resolution for the same detector coverage area. The sub-millimeter isotropic pixel pitch allows improved image resolution. The photodiode array of the

AS5951 consists of 16 x 8 pixels with a pitch of 0.98 x 0.98 mm², thereby improving the original 0.98 x 1.96 mm² pitch of its predecessor. This allows twice the spatial resolution for a total sensor dimension of 31.23 mm using two AS5951s to implement a 32-slice detector. To accommodate the higher pixel density, the number of channels of the A/D converter (ADC) is increased from 64 to 128. The pixel dimensions can be customized within short development cycles to meet customer requirements.

Another influence on image performance is the low dark current of maximum 1 pA, which is achieved by an automatically calibrated near zero-offset voltage at the photodiode. This is 90 percent lower than in the

AS5950 device and allows for better low dose performance. The input related noise performance is a crucial aspect for image quality. Noise performance is extremely low in the

AS5951 due to the short connection of photodiode and ADC channel and allows improved low dose performance.

The AS5951 has two modes of operation: high-resolution mode and low dose mode. In the high-resolution mode, a maximum noise of 0.30 fC is achieved for an input current range of 200 nA. In low dose mode, two pixels are binned to a larger pixel at a noise level of 0.43 fC, which improves signal-to-noise performance and allows a dose level reduction. The high linearity of ±600 ppm, including photodiode, also ensures artefact-free images.The minimum integration time of 200 µs allows fast CT detector rotations. The digital data readout can be accessed via the SPI interface.

The AS5951 as a cost-optimized solution for 32-slice CT detectors

The patented product design of ams OSRAM allows the 128-channel ADC to be monolithically integrated into one single device and not placed as a discrete component next to the array of photodiodes. This reduces complexity and manufacturing costs for CT detector vendors. To assemble the large pixel array of the CT detector, the AS5951 is mounted on its three adjacent edges. Two AS5951 ICs can be placed in the Z-direction (axial), enabling the development of 32-slice detectors for price-sensitive CT detectors. The internal reference voltage reduces material costs by eliminating the need for an additional external component. An integrated temperature sensor monitors the temperature at the chip. With the AS5951, customers receive a ready-to-use sensor chip solution that simplifies system integration with the detector.

In addition, self-heating is reduced with a maximum power dissipation of 67.2 mW per sensor in low dose mode, which decreases cooling costs. To produce a CT module, the AS5951 can be mounted directly on a substrate using a wire bonding process. In combination with low cost substrate materials, the AS5951 provides a cost effective module solution for CT detectors. This is key to increasing access to diagnostic CT imaging around the globe.