October 29th 2021, Saphlux Incorporation, a spin-off company from Yale University, announced the full-color NPQD

® Micro-

LED array with a sub-pixel size of 2 µm, an important breakthrough in AR display developments.

【2µm R-G-B NPQD® Micro-LEDs】

Due to the difficulties of mass-transferring small size (<10 µm) micro-LEDs, most AR displays are fabricated using monochrome wafer bonding. How to achieve a full-color conversion became a universal challenge.

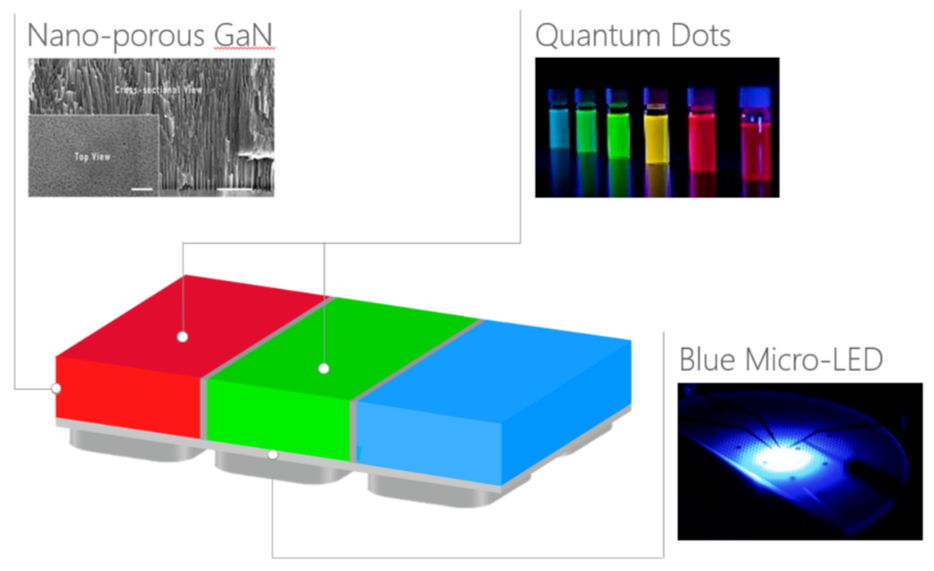

Traditional color conversion technologies including QD printing and QD lithography can hardly meet the requirements because of the large printing line width, low conversion efficiency, high QD-film thickness, and poor reliability. Utilizing the patented NPQD® technology, Saphlux team created a nanoporous GaN layer inside micro-LED epi-wafer as a natural vessel for quantum dots to be selectively loaded in. A 2 µm full-color micro-LED array was then fabricated and lit up to prove the feasibility.

NPQD® color conversion technology

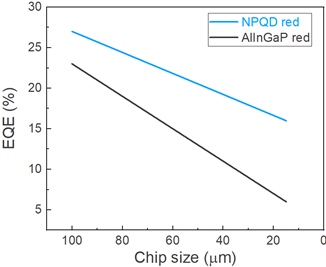

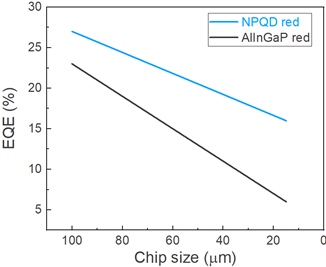

Moreover, conventional AlInGaP based red micro-LED suffers from severe efficiency loss as the chip size shrinks because of the high defect density and poor light extraction. This problem is now addressed by converting the high-efficiency blue micro-LEDs into red through NPQD®. The optimized nanoporous GaN provides a strong scattering effect which increases the effective light path by 8 times and the emitting area by 40 times. With that, a 99.99% light conversion efficiency can now be achieved with a merely 5 µm layer.

EQE comparison between NPQD® and AlInGap micro-LEDs

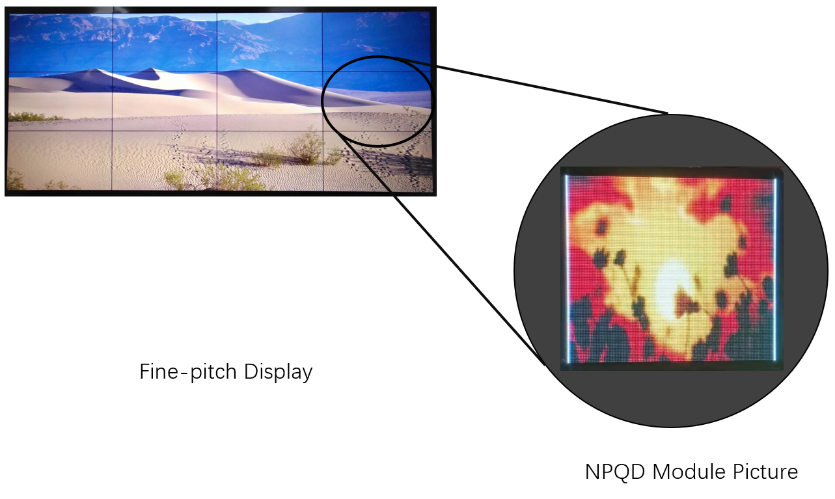

Saphlux also announced today that the company has started the production of NPQD® R1 and T1 micro-LED chips for fine-pitch display customers, who have qualified these chips on their display products and are now entering into the delivery phase. This proves the maturity of the NPQD® technology – a breakthrough in lab research finally evolves into a commercial product.

NPQD® Micro-LED fine-pitch display