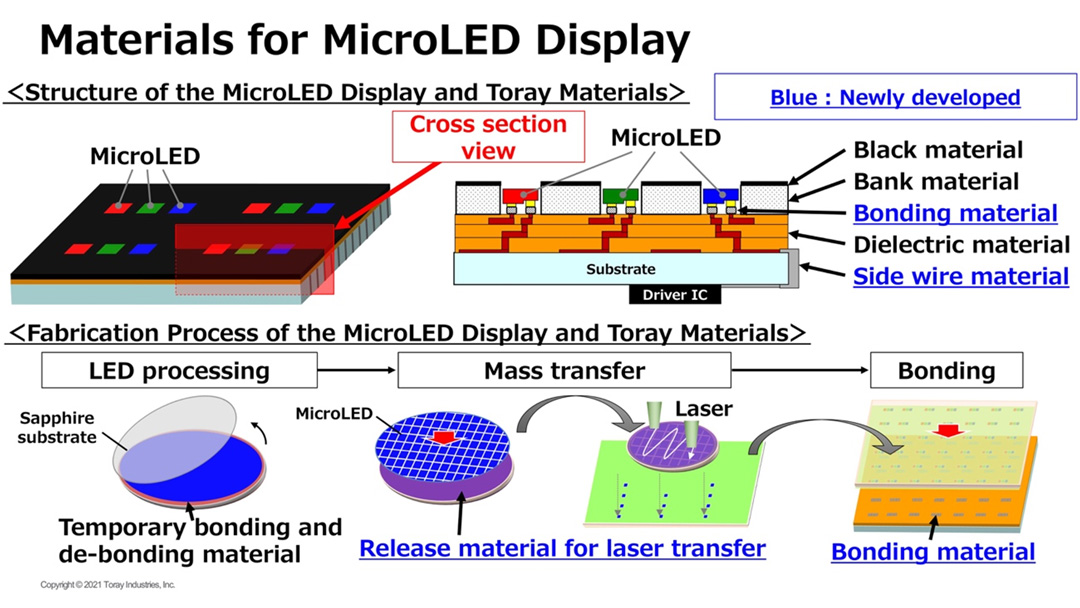

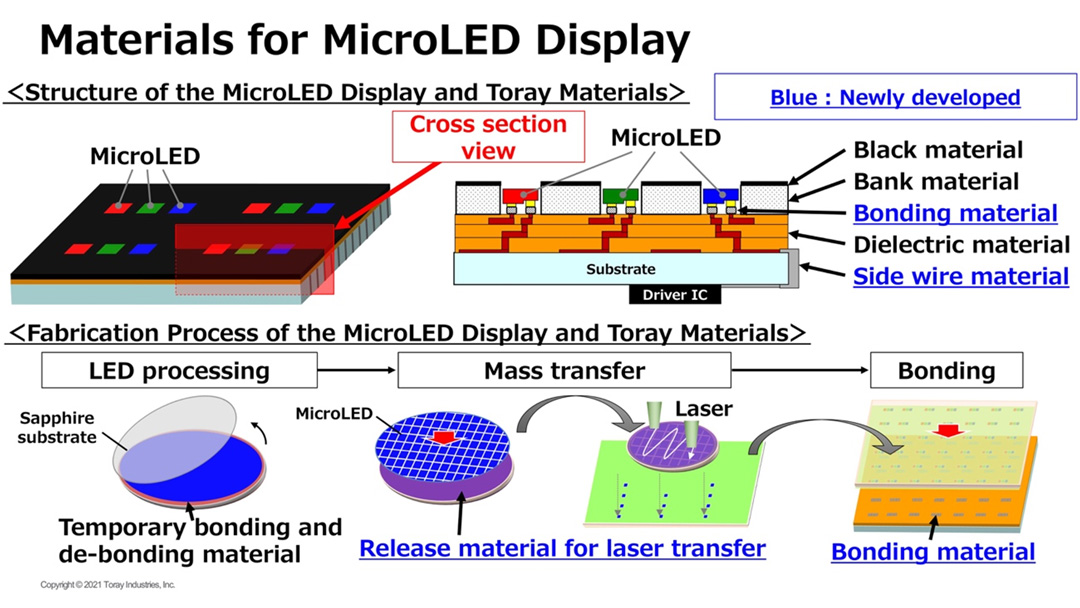

Tokyo, Japan, December 7, 2021 – Toray Industries, Inc., announced today that it has de-veloped a laser transfer release material to swiftly arrange light-emitting diode (LED) chips, a material that simplifies bonding between LEDs and wiring, and a substrate side wire material that helps enlarge displays, in collaboration with its subsidiary Toray Engi-neering Co., Ltd. The new materials are vital for creating microLED displays and enhanc-ing their performance.

The Toray Group looks to contribute to microLED display progress and mass production by offering total solutions for the diverse material and equipment for the fabrication and in-spection.

MicroLED displays offer tremendous potential for their outstanding performance and small environmental footprints. That is because these advanced devices offer exceptional brightness, color gamut, contrast, and reliability. Another benefit is that their power con-sumption is low because of the high luminous efficiency of their LEDs.

The challenge has been to come up with technology to swiftly achieve regular arrange-ments of numerous microLED chips and reduce fabrication costs sufficiently to drive their widespread adoption. The new laser transfer material enables fast placement of numer-ous LED chips in any position on a substrate in the display manufacturing process.

The new laser transfer material enables fast placement of numerous LED chips in any po-sition on a substrate in the display fabrication process. Using this material with Toray Engi-neering’s laser transfer and inspection equipment can accelerate microLED production. It is also possible to create displays free of color irregularities through selective placement that reflects the color tone of each LED chip.

The new bonding and substrate side wire materials are the fruit of further work on RAYBRID®, a proprietary photosensitive conductive material.

The material that connects LED chip electrodes to metal trace on the substrate enables faster joint formation at lower temperatures and lower bonding force compared to the conventional connection methods. It is accordingly easier to replace defective LED chips, which has been a challenge to date, and helps improve yields during manufacturing.

The substrate side wire material transmits signals from the surface to the back of a sub-strate. This simplifies the wiring formation process and makes it possible to seamlessly line up and enlarge multiple displays.

Toray has already mass-fabricated microLED display materials. They include dielectric ma-terials for wiring LED chips, black materials for enhancing display blackness to achieve high contrast, and temporary bonding and de-bonding materials for thinning or peeling off LED chip substrates. It aims to augment its lineup with bank materials for more colors and exceptional brightness.

Toray accordingly seeks to broaden its lineup of materials for microLED displays and com-bine them with Toray Engineering’s fabrication and inspection equipment. This is to offer total solutions for microLED display manufacturing and contribute to mass fabrication of microLED displays.

Toray will continue leveraging its core technologies of synthetic organic and polymer chemistry, biotechnology, and nanotechnology to research and develop advanced materi-als that transform societies in keeping with its commitment to innovating ideas, technolo-gies, and products that deliver new value.

Toray Electronics and Information Materials

https://www.electronics.toray/en/

About the online seminar Micro LEDforum 2021

Dates: Sept. 8, 2021 (Wed.)–Dec. 10, 2021 (Fri.)

Language: Mandarin (Chinese subtitles available)/English (Simultaneous subtitles in English and Chinese)

Contact persons: