2024-06-28

2024-06-28

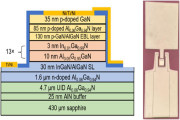

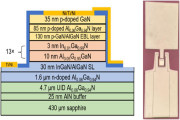

University of Wisconsin-Madison in the USA reports on atomic layer deposition (ALD) passivation as a means to overcome the impact of sidewall damage on micron-scale light-emitting diodes (micro-LEDs), resulting in near size-independent performance between 8μm and 100μm [Guangying Wang et al, physica status solidi (RRL) published online 23 May 2024].

The researchers comment on smaller devices: “Micro-LEDs have the potential to show higher stability under high current density while providing a higher light extraction efficiency and output power than regula...

Continue reading →

2021-12-20

2021-12-20

The UK’s Oxford Instruments Plasma Technology, a supplier of plasma etch and deposition high-volume manufacturing (HVM) solutions, has had its remote-plasma atomic layer deposition (ALD) nitride passivation solution qualified for full production by a US-based power electronics manufacturer of gallium nitride (GaN) devices, supporting the first phase of its ramp.

GaN-based devices are now well established in the consumer market, with a wide range of rapid chargers available commercially to support mobile devices. Fast charging and a smaller footprint are among the...

Continue reading →

2021-04-13

2021-04-13

ESPOO, Finland, April 13, 2021 /PRNewswire/ -- Picosun Group has proved to significantly increase the production efficiency of its LED and OLED customers with the PICOSUN® P-300BV ALD system. Recent tests show that a reduced ALD process cycle time and an increased number of wafers deposited with the same film thickness resulted in almost 100% better throughput. A throughput of over 20 000 wafers per month can be reached with a wafer batch of 100 wafers*. At the same time, the process quality in terms of film thickness uniformity has remained on an...

Continue reading →

2024-06-28

2024-06-28

2021-12-20

2021-12-20

2021-04-13

2021-04-13